FDG Valves are designed to handle the toughest flow problems in various industrial applications. FDG Technologies offers a worldwide engineering, sales and customer service network to help you select the best valve choice for your toughest application.

LINING MATERIALS FOR ANY OPERATING CONDITIONS

PTFE (Polytetrafluoroethylene)

PTFE has excellent properties such as chemical inertness, heat resistance (both high and low), electrical insulation properties, low coefficient of friction (Static 0.08 and Dynamic 0.01 ), and nonstick property over a wide temperature range up to 260°C. It has a density in the range of 2.1 to 2.3 g/cm³ and melt viscosity in the range of 25 mPa.s (cP). Molecular weight of PTFE cannot be measured by standard methods. Instead, an indirect approach is used to judge molecular weight. Standard Specific Gravity (SSG) is the specific gravity of a chip prepared according to a standardized procedure. The underlying principle is that lower molecular weight PTFE crystallizes more extensively, thus yielding higher SSG values.

TFM (Modified PTFE)

The new generation of chemically modified PTFE enhances the performance of classic PTFE by providing outstanding low deformation under load, compression stress relaxation (recovery), reduced permeation, fewer voids, increased surface smoothness and good welding characteristics

PFA (A POLYMER OF TETRAFLUOROETHYLENE AND PERFLUOROVINYLETHER)

PFA polymers are fully fluorinated and melt-processible. They have chemical resistance and thermal stability comparable to PTFE. Specific gravity of perfluoroalkoxy resins is in the range of 2.12 to 2.17. PFA has an upper continuous use temperature of 260°C crystallinity and specific gravity of PFA parts decrease when the cooling rate of the molten polymer is increased. The lowest crystallinity obtained by quenching molten PFA in ice was 48% (specific gravity 2.123).

FEP (A POLYMER OF TETRAFLUOROETHYLENE AND HEXAFLUOROPROPYLENE)

Fluorinated ethylene-propylene copolymers are fully fluorinated and melt-processible. They have excellent chemical resistance and thermal stability. Specific gravity of FEP resins is in the range of 2.13 to 2.15. FEP has an upper continuous use temperature of 200°C.

ETFE (A POLYMER OF TETRAFLUOROETHYLENE AND ETHYLENE)

PVDF and equimolar ETFE are isomers but the latter has a higher melting point and a lower dielectric loss than the former. ETFE crystallizes into unit cells believed to be orthorhombic or monoclinic. The molecular conformation of ETFE is an extended zigzag. This polymer is dissolved in some boiling esters at above 230°C, thus allowing determination of molecular weight (weight-average) by light scattering. ETFE has several transitions, alpha relaxation at 110°c {shifts to 135°C at higher crystallinity), beta at 25°C, and gamma relaxation at 120°c. ETFE terpolymers have good mechanical properties including tensile and cut-through resistance and lower creep than perfluoropolymers. ETFE is more resistant to radiation than perfluoropolymers (modestly affected up to 20 Mrad) and can be crosslinked by radiation such as electron beam. Crosslinking is used to strengthen cut- through resistance of ETFE wire insulation.

ECTFE

Halar® ECTFE is a partially fluorinated semi-crystalline polymer offering a unique combination of properties for highly demanding industries.

• Outstanding chemical, permeation and fire resistance

• Low permeability

• Excellent weatherability

• Excellent release properties

• Good abrasion resistance

It is widely used in anti-corrosion applications as a lining or in self-supporting constructions (piping). Its excellent fire resistance properties and chemical resistance make Halar ECTFE a product of first choice in wire and cable applications, in communication cable or speciality cable.

PPH

Polypropylene is available in two basic types as either homo polymer or copolymer material. Although similar in many respects each type exhibits distinct differences in both appearance and performance. Polypropylene Homopolymer (PPH) is the most widely utilized. PPH offers a high strength to weight ratio and is stiffer and stronger than copolymer, this combined with good chemical resistance and weldability allows this material to be used in many corrosion resistant structures.

PFA (CONDUCTIVE)

3M Dyneon Fluoroplastic PFA is an electrostatic dissipative fluorothermoplastic compound consisting of a fully fluorinated PFA base polymer and an electroconductive carbon black. The product has specifically been developed for transfer moulding.

• Electrostatic dissipative

• Processing : Transfer moulding

• Wide service temperature range upto 240°C

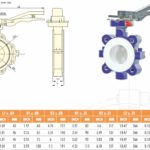

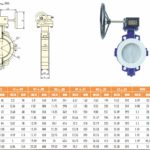

FDG BUTTERFLY VALVES

Heavy duty lined butterfly valves for aggressive and abrasive liquids and sludges

DOWNLOAD BUTTERFLY VALVES CATALOGUE

FDG BALL VALVES

Heavy duty lined ball valves for highly aggressive and abrasive medias

DOWNLOAD BALL VALVES CATALOGUE

Key industries where FDG valves are used:

MINING INDUSTRY

Precious Metal Mining

– Gold and Silver

– Copper

– Recirculation Water

– Concentrate Lines

– Concentrators

– Circuit Sizing and Reduction

Aluminum / Bauxites

– Aluminum Oxide

– Mud Washing

Phosphates Mining/processing

– Diammonium Phosphate

– Drying and Filtering

– Recausticizers

– Pelletizing

Coal industry / Iron Ore / Tar Sands

– Dilute Coal Dust

– Bitumen

– Lead

– Iron Ore Reduction

– Pelletizing

– Potash

CHEMICAL INDUSTRY

General applications

– Emulsive Chemicals

– Deacidification stations feed

– Catalyst Feed Systems

– Industrial Treatment

PULP AND PAPER

General applications

– pH adjustment

– Cyclones Discharge

– Recycled Paper

– De-Inking

POWER INDUSTRY

General applications

The design of FDG valves allows to widely use them with wet slurries such as and lime. Examples of the most common processes: FGD systems (flue gas desulfurization), wet lime scrubbers, fly ash, bottom ash and coal handling.

CEMENT/ SAND / SILICA

General applications

– Cement production

– Silica production

– Glass Production

– Sand Transfer Lines

– Ceramics Manufacture

– Production of Roofing Materials

– Sand Transfer Lines

WATER AND WASTEWATER TREATMENT

Water pre-treatment and treatment

– Pre-Treatment Basins

– Carbon Slurry

– Polymer Feed Systems

– Blackwater Control

– Ferric Chloride

– Stormwater and Sewers

FOOD / AGRICULTURAL INDUSTRY

General applications

– Grapes After Crushing for Wine

– Grains After Brewing for Beer

– Soap Wastes and Tallow

– Fertilizer Application

– Aeration of Fish Lagoons

– Seeds and Skins Removed from Fruit

– Hulls and Shells Removed from Nuts

– Sugar By-Products After Refining

– Skins and Rinds After Processing

– Animal Waste After Butchering

– Animal Manure

– Effluent Discharge

– Wastewater from Tanneries

– Wastewater from Washing and Boiling