FDG has substantial export business pertaining to both Control Valves & Actuators to countries in Europe, USA & Middle East, besides local sales catering to Power, Nuclear, Sugar, Fertilizers, Oil and Gas, Chemical, Steel, FMCG sectors, etc.

FDG has in-house capability & expertise to design, engineer, manufacture Specialty Valves for Critical application besides our standard range of Valves, Accessories & Actuators. We use Best in Class software for 3-d Modelling, Simulation & Analysis (FEA & CFD). Our Designs are based on standards viz; ANSI, ASME, API etc. We are ISO 9001 certified for Quality Management System.

Single Seated Globe Control Valve (Series 10)

Superior Performance in liquid and Gaseous services with low cost of ownership.

Rugged construction proven over the years

Features

• Use of Contoured Plug Design for low pressures and Pressure drops

• Use HF (High Friction) family of single I multistage cage

guided trims to prevent onset of cavitation in

liquid services and attenuate noise in Gas applications

• High Flow capacity and High Gain

• High Rangeability

• Pilot Operated Design for Leakage Class V (Metal Metal Seating) at elevated temperatures

• Special metallurgy available on request

• Special Actuations with Multi spring I Electrical Actuators available

• Extremely low flow trims available

• Jacketed valves: Jacket on the valves ensure consistent heating or cooling of process media to prevent crystallization or siezing of flow media.

Specifications

Valve Type: Linear Single Seated Globe

Size: 1/2″ to 16″ (Larger Sizes available on request) Rating: ASME Class 150-2500

Materials: Carbon Steel, Stainless Steel, Special Alloys

Application

The industry choice for reliable, tough globe valve. Handles a wide range of control applications for flow, pressure and temperatures, including corrosive fluids steam, water, gases, multi phase, high temperatures, erosion and high pressure drop applications.

Finds applications in Nuclear, Oil and Gas, Fertilizers, Steel, Power plant, Chemicals, Pharmaceutical and Food industries.

Special PTFE Globe Control Valve

FDG Technologies offers Series 10 PTFE Control Valves which are specially designed to withstand highly Corrosive fluids in Chemical, Pharmaceutical and Fertilizer Industries.

Sizes: 1/2″, 3/4″,1″,1.5″and 2″ Rating as per ASME Class 150

Sizes: 1/2″, 3/4″,1″,1.5″and 2″ Rating as per ASME Class 150

Maximum Pressure handled

– 10 kg/cm2g with standard bonnet

– 4 kg/cm2g with PTFE bellows

Maximum Temperature

– 150 °C

PTFE Valves are developed to cater to the process where very corrosive fluids are involved and cost of exotic metals becomes prohibitively expensive apart from scarce

availability.

PTFE ( Poly Tetra Fluro Ethylene) being inert is corrosion resistant to most of the fluids.

Application

Highly corrosive fluids.

Double Seated Globe Control Valve (Series 20)

Superior Performance in liquid services with large flow capacity in comparison to Single Seated Valves Rugged construction proven over the years.

Features

• High Flow capacity

• Heavy Top and Bottom Guiding

• Minimum differential plug areas to reduce actuator thrust requirements

• Optional Anti Cavitation I Low Noise Trim

Options available

• Special Actuations with Multi spring I Electrical Actuators available

• Special metallurgy available on request

Specifications

Valve Type: Double Seated Globe

Size: 1/2″ to 18″(Larger Sizes available on request) Rating: ASME Class 150-600

Materials: Carbon Steel, Stainless Steel, Special Alloys

Application

The choice for reliable, tough double seated globe valve, finds applications in Oil and Gas, Fertilizers, Steel, Power plant Chemicals, Pharmaceutical and Food industries.

Three Way Globe Control Valve (Series 30)

The 3-way Control valve is designed to precisely Control water,steam, hot oils and other industrial fluids for mixing or diverting applications.

Features

• High Flow capacity

• The internal valve trim is designed to ensure long service life, avoiding unnecessary maintenance

• High rangeability

• The same construction may be used for both converging and diverting applications

Specifications

Valve Type: 3 Way Globe (Mixing/Diverting)

Size: 1/2″ to 12″(Larger Sizes available on request) Rating: ASME Class 150-600

Materials: Carbon Steel, Stainless Steel, Special Alloys

Application

3-Way Globe Control Valve is the choice where accurate temperature control in heat exchanger applications is needed.

Finds extensive use in Chemicals & Paint Industry where hot oils are used extensively.

Pressure Reducing Valve (Series 60)

Pressure Reducing Valve is self-actuated to keep downstream or upstream pressure regulated.

Features

• Does not require any external I auxiliary energy.

• Uses Line Pressure Energy to Control.

• Low maintenance.

• Valve Disc is reversible and can be changed quickly for renewed life.

• Pressure Balanced design, any fluctuations in the inlet pressure has negligible effect on regulated pressure.

Specifications

Valve Type: Self Actuated Pressure Reducing Valve Size: 1/2″ to 8″

Rating: ASME Class 150- 300

Materials: Carbon Steel, Stainless Steel

Application

Pressure Reducing Valves are used extensively in Fertilizers, Chemical process, and Pharmaceutical and Natural Gas distribution industry.

Angle Globe Control Valve (Series 70)

Angle control valves are most commonly used to let down pressure, regulate level and flow.

Features

• High Flow capacity

• Tight Shut Off

• High Rangeability

• Wide range of interchangeable trim styles and sizes available

• Adaptability to special duties

ie venture outlet, low noise etc.

• Special metallurgy available on request.

Specifications

Valve Type: Angle Globe

Size: 1/2″ to 6″ (Larger Sizes available on request) Rating: ASME Class 150-2500

Materials: Carbon Steel,Stainless Steel,Special Alloys

Application

The choice for globe valve for severe letdown applications and where fluid contains solid particles. Finds applications in Oil and Gas (Coal gasification and liquefaction), Fertilizers, Petrochemicals (PTA, polymers PET, PBT, Polyurethane, PVC etc.}, Power plant applications and Chemicals industries.

Butterfly Control Valve (Series 80s)

Butterfly valves are designed for isolation on/off service, as well as for control. Shutoff is provided by a variety of seals which include metal, PTFE and other elastomer seats.

Features

• Wafer Style End Connection (Flanged connection on request)

• Concentric, Eccentric, Double Eccentric option

• Choice of various elastomers or PTFE Sleeve

• Tight shut off with elastomer Sleeves

• Minimum obstruction for flowing media

• Very high Cv to body size ratio

• Simple and light construction

• Ease of Installation

• Low maintenance

Specifications

Valve Type: Butterfly Size: 2″ to 36″

Rating: ASME 150-300

Type: Concentric I Eccentric I Double Eccentric Materials: Carbon Steel,Stainless Steel, Special Alloys Seats: Metal, PTFE, Neoprene, Viton, Silicone, EPDM or other elastomers on request.

Actuators: Spring and Diaphragm (Linear), Rack and Pinion or Scotch Yoke (Rotary).

Application

Butterfly Valves offer an economical solution for handling gases and liquids, that are easily displaced, by the valve disc as it closes. Butterfly valves provide a reliable, bubble-tight, bi-directional shut off.

Finds extensive application in Steel, Paper,Sugar and Textile Industry.

Ball Control Valve (Series 90)

Ball Valves are versatile valves designed for throttling control of fibrous suspension applications plus clean, dirty,viscous and corrosive liquids and gases. They are designed to meet the highest industry standards for dynamic performance.

Ball Valves are more compact, lighter weight and less expensive than comparably sized globe valves.

These valves exceed leakage Class VI offering bubble-tight shutoff. Other features include superior rangeability and repeatability.

Features

• Bubble Tight shut off

• For modulating and On Off control

• Minimum obstruction for flowing media

• High flow capacity

• ‘O’Ball & V Notch Construction available

• Ease of Installation

• Low maintenance

Specifications

Valve Type: Ball.

Size: 2″ to 8″( Higher Sizes on request).

Rating: ASME Class 150-600 ( Higher rating on request). Type: Floating Ball/Trunion Mounting.

Materials: Carbon Steel,Stainless Steel ,Special Alloys Seats: PTFE , RPTFE, PEEK

Actuators: Spring and Diaphragm (Linear), Rack and Pinion.

Application

Ball Valves are used in Paper, Pulp and Textile Industries.

Available with API 60/CE certification

Bellow Sealed Valve

Bellow Sealed valves are designed to eliminate valve leakage, through gland, also known as Zero Leak Valves. This is available as an additional feature to give total leakproof packing in Single Seated, Double seated and Three way Control valves.

Features

• Stainless Steel Bellows are used to withstand high pressure and temperature

• PTFE Bellows are available for low pressures and temperature upto 180 Deg C.

• Hastealloy I Monel Bellows are available for

corrosive application.

• Eliminates product losses, hazards to humans, the environment and costly downtime required for packing maintenance.

Application

Typical applications of valves include hazardous and corrosive chemicals like Chlorine, Ammonia, Phosgene, Butadine, Benzene, Ethylene, Hydrochloric acid, Hydrogen, Thermic fluid, Fatty acids to name just a fraction of the varying possible uses.

Desuperheaters (Series 40)

In many manufacturing processes, steam is superheated and distributed at high-pressure for efficiency. Pipeline Desuperheaters are designed to reduce the temperature of superheated steam for optimal heat transfer and efficiency.

Features

• High Rangeability variable spray unit

• Control within 6°C above saturation temperature

• Accurate and repeatable control of Fluid temperature

• High Spray water pressure capability

• Wide range of available nozzles

• Erosion resistant materials of construction

• Ease of Installation

• Low maintenance

Application

Desuperheater systems provide a convenient method of reducing superheated steam or other vapours to temperatures approaching saturation, generally applicable to Power and Sugar industry.

Power Cylinder

Various types of opening and closing can be performed by changing the linear motion of power cylinders into turning force through link mechanisms or by using the linear motion as it is.

Features

• Higher Strokes

• Stay put Action

• Can be given with Smart Positioners

• Low maintenance

Specifications

Type: Double Acting Pneumatic Power Cylinders Bore Size: 3″ to 12″ (Higher bore size on request} Stroke: Upto 16″ (Higher stroke on request} Maximum Working Pressure: 150 Psig

Maximum Working Temperature:

• 80 °C with Nitrile Seals

• 250 °C with Viton Seals Air Consumption: 1.0 SCFM

Application

Finds extensive applications in Opening and Closing of Hopper Gates, lids of Drying Furnaces Dampers, Butterfly Valves and for specific applications like control of FD and ID Fans in Boilers

Procon Diaphragm Valve

A diaphragm valve is a manual or control type block valve which uses a diaphragm as the closing device. The diaphragm valve is usually used to isolate or block flow. Because the material of the membrane can chemically degrade, diaphragm valves are limited for use at low pressures and a limited temperature operating range.

Features

• Diaphragm valve conforms to BS:5156 (Series’S’)

• Body Casting Standardized to FG 200 grade cast Iron

• Better sealing and longer diaphragm life with help of Weir Design

• Stronger Bonnet Design to take care of higher thrust and support to the diaphragm

• Diaphragm designed for long life

• Fail safe action on auto valves totally protects process operation in the event of electrical power or air failure

• Available in different linings like, Ebonite, Neoprene, Hyplon, Hylar, PFA, Glass etc. to handle different fluids.

Specifications

Type: Weir Type Diaphragm Valves

ngs: ASM E Class 125/150

Application

Finds extensive applications in Caustic Soda plants, Chemical plants, Effluent I Sewage Treatment plants, Fertilizers and

Water demineralization, desalination applications. The diaphragm valve has an extended use for applications at low pressures and slurry fluid where most other kinds of valves corrode or become obstructed.

Actuators

Specifications

• Size: 38 to 300 Sq inch for Spring and Diaphragm Actuators

A pneumatic actuator converts energy (typically in the form of compressed air) into mechanical motion.

FDG manufactures pneumatically operated actuators in house.

Features

• Higher Power

• Fast Response

• Low Hysteresis

• Field reversible (Except Model 38E and Multi Spring Actuators)

• Limit Stops available

• Flexibility in Selection of Springs

• Manual Override (Handwheel) can be provided in Top Mounted Design or Side Mounted Design.

• Sizes: 75 to 450 Sq Inch for Piston Actuator

• Type: Single Spring Diaphragm Actuators, Piston actuators and Multi Spring Diaphragm Actuators

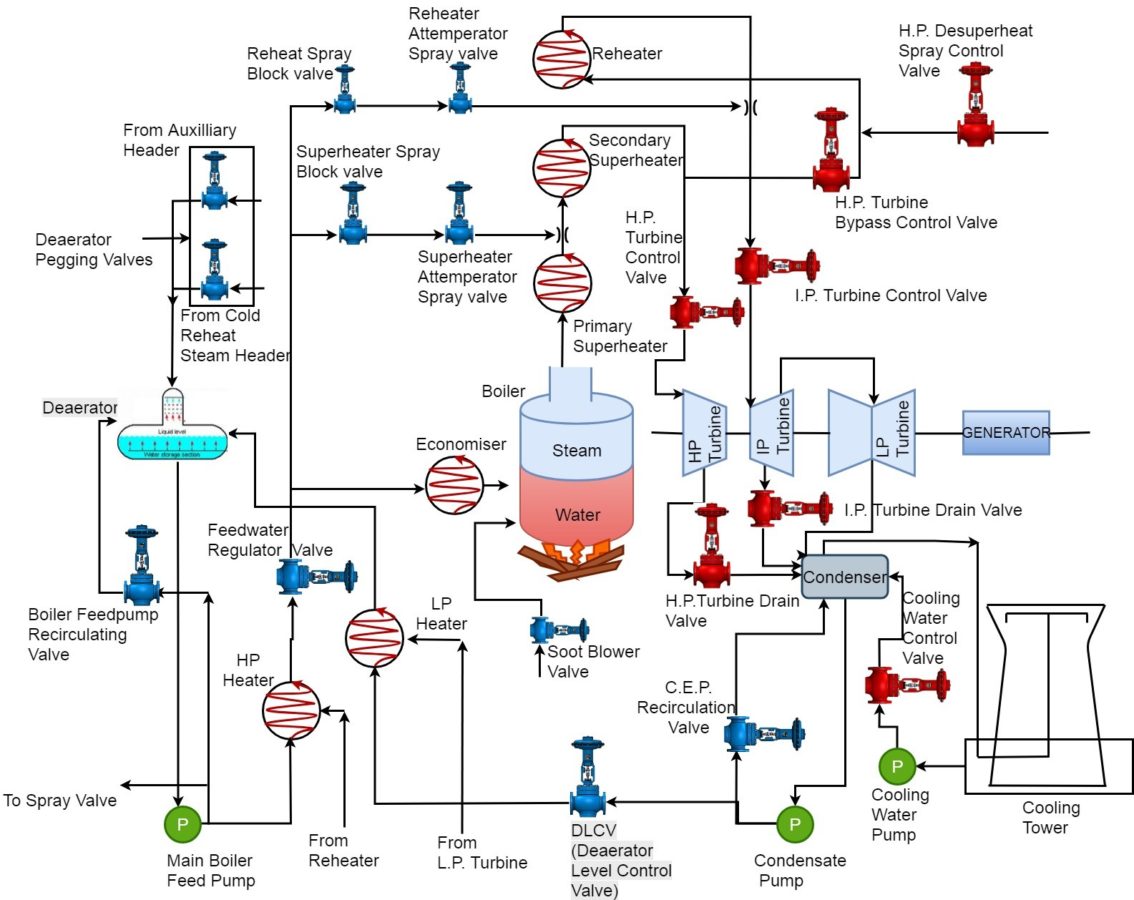

POWER PLANTS APPLICATIONS

Power plants have immensely complicated facilities involving many systems and demanding the use of critical Instrumentation and control valves. FDG Technologies deliver individual solutions matched to our customer requirements and specification for the power Industries.

We provide best solution to all the complicated systems involved, such as:

• Condensate System.

• Feed water System.

• Main steam System.

• PRDS (Pressure Reducing Desuperheating System).

Fig: General Schematic of Power Plant System

(Note: Valve’s shown in blue are under standard product range)